Date: April 16, 2024

We at WAISL are confident and excited about the future and the advent of smart airports. In this era of heightened demands, the need for efficient, secure, and sustainable operations has become paramount. Smart Airports emerge as the revolutionary solution, leveraging cutting-edge advancements in Artificial Intelligence (AI), Internet of Things (IoT), and advanced data analytics – thereby creating a path-breaking solution.

This transformative approach will reshape the aviation landscape, offering a seamless and exceptional experience to passengers, operators, and the environment alike. But at the heart of (or rather the brain of) this transformation are new-age innovations and techniques.

The digital twin is one such technology. It’s an integral component driving the current evolution of airport ecosystems, and an underpinning feature of the APOC. Let’s explore insights of the system and answer common queries as we navigate the realm of Digital Twins – what it is, what role it plays, its types, benefits and more.

A digital twin refers to a virtual portrayal of an object or system, encompassing its entire lifecycle, which is continuously updated using real-time data. It is a combination of machine learning, reasoning and simulation all working together to facilitate the decision-making processes.

Essentially, a sophisticated virtual model is created that mirrors the physical entity with utmost precision. This entity could range from being a car, building, bridge, to being a jet engine. Or an airport, in case of the APOC. Sensors connected to the physical asset to gather data, which is then mapped onto the virtual model. Observers of the digital twin gain access to vital information regarding the real-world performance of the physical object.

The concept was initially introduced in 1991 with “Mirror Worlds”, a book published by David Gelernter. However, the formal application of the digital twin concept to manufacturing is credited to Dr. Michael Grieves, who announced it in 2002 while he was on the faculty at the University of Michigan. The term “digital twin” was officially coined by NASA’s John Vickers in 2010.

Despite being introduced in the late last century, the foundational idea of utilizing a digital twin for studying a physical object has roots much earlier. NASA was the pioneer in digital twin technology during its space exploration missions in the 1960s. At that time, each spacecraft was diligently replicated on Earth, serving as a basis for study and simulation by NASA personnel involved in space exploration missions.

A digital twin functions by recreating a physical asset, digitally, in a virtual environment, encompassing its functionality, features, and behavior. Utilizing intelligent sensors, real-time data is collected from the product to construct a digital representation of the asset. This representation is applicable throughout the asset’s lifecycle, spanning initial product testing, real-world operations, and decommissioning.

The Unique characteristics of Digital twin make it a pivotal part of Industry 4.0 and our APOC.

Digital twins within APOC in airports serve the dual role of visualizing and promoting the present and anticipating the future. Essentially, these virtual replicas play a crucial role in assisting engineers and operators in comprehending not only the current performance of products but also predicting their future behaviour. The analysis of data from connected sensors, combined with other information sources, empowers the generation of such predictions. Armed with this foresight, organizations can expedite learning processes and transcend traditional barriers related to product innovation, intricate lifecycles, and value creation.

Digital twins empower manufacturers and engineers to achieve various objectives, such as:

Digital twins transcend being merely a set of tools; they act as a comprehensive window into projects at every stage of design, development, and utilization. In the aviation industry, digital twins play a transformative role in the lifecycle of constructed assets by ensuring data continuity between different project phases. By providing a multi-dimensional perspective, a digital twin offers insights into how an airport facility or asset is designed, constructed, and performs throughout its entire lifecycle.

As the operational building data enriches the digital replica, it becomes feasible to forecast system failures, conduct “what-if” simulations, and gain valuable insights into the performance operational workflow, and utilization of the built asset. This accumulated knowledge can be harnessed to plan future projects and enhance design decisions, ultimately contributing to the development of more sustainable buildings and infrastructure.

Digital twins in APOC come in various types, each determined by the level of product magnification.

The primary distinction among these twins lies in their application areas. It is common for different types of digital twins to coexist within a system or process. Let’s explore these digital twin categories to understand their distinctions and applications.

Component twins represent the fundamental unit of digital twins, serving as the smallest functional example of a component. Parts twins are essentially similar but are associated with components of slightly lesser significance.

When two or more components collaborate, they form an asset. Asset twins allow for the examination of the interaction among these components, generating a wealth of performance data ready to be turned into real-time actionable insights.

The next stage of magnification involves system or unit twins, providing insight into how different assets converge to create a fully operational system. System twins offer visibility into asset interactions and may suggest opportunities for performance enhancements

At the macro level of magnification, process twins unveil how systems collaborate to establish an entire production facility. They address questions such as whether these systems are synchronized for peak efficiency or if delays in one system affect others. Process twins assist in determining precise timing schemes that significantly impact overall operational effectiveness.

Digital twins operate across five levels of sophistication, ranging from basic data integration to full autonomy. These levels include:

The descriptive twin serves as a dynamic, editable representation of design and construction data, essentially a visual duplicate of a constructed asset. Users can specify the desired information and data extraction criteria.

At this level, an informative twin incorporates an additional layer of operational and sensory data. It captures and consolidates defined data while ensuring the verification of data to ensure seamless system integration.

A predictive twin utilizes operational data to glean insights, similar to a car notifying you when it’s time for an oil change.

This tier involves a twin that simulates future scenarios and contemplates “what-if” questions, providing a more comprehensive understanding of potential outcomes.

An autonomous twin possesses the capability to learn and take actions on behalf of users, representing the pinnacle of digital twin sophistication.

It’s worth noting that levels 1 and 2 are currently in use within the APOC in airport, while levels 3, 4, and 5, enhanced with real-time information from embedded sensors and IoT technologies, are poised for future implementation.

Digital twins contribute to more efficient research and product design by generating extensive data on potential performance outcomes. This wealth of information facilitates insights that empower companies to refine products before initiating the production phase.

Beyond the production phase, digital twins serve as valuable tools for mirroring and monitoring production systems, aiming to achieve and sustain peak efficiency throughout the entire manufacturing process.

Digital twins in APOC in Airports optimize work processes, enhancing the production chain, reducing process-related investments, and leading to cost savings by streamlining operations.

Through the processing of information and data, digital twins aid in the early detection of potential errors in prototypes, enabling proactive solutions to prevent disruptions in the real twin’s system.

Digital twins enable the anticipation of problems, allowing for prompt resolution and the implementation of improvements at various levels in the production chain. This proactive approach helps in minimizing maintenance requirements.

Even at the end of a product’s lifecycle, digital twins play a key role in helping manufacturers decide the appropriate course of action, such as recycling or other measures. By utilizing digital twins, manufacturers can determine the salvageable materials from the product.

A substantial transformation in existing operational paradigms is undeniably underway. Asset-intensive industries are currently experiencing a digital reinvention that disruptively alters operating models, necessitating an integrated perspective encompassing both physical and digital aspects of assets, equipment, facilities, and processes. Digital twins play a pivotal role in this realignment, assisting organizations in proactively navigating digital disruption by comprehending evolving customer preferences, customizations, and experiences. This knowledge empowers businesses to expedite product delivery, ensuring higher quality from components to code. However, the potential of digital twins extends even further.

The incorporation of cognitive computing enhances the capabilities and scientific dimensions of digital twins. Technologies such as NLP, ML, object/visual recognition, acoustic analytics, and signal processing are among the features that amplify traditional engineering skills. This cutting-edge technology continues to provide the insights necessary for enhancing product quality and optimizing processes, pushing the boundaries of what digital twins can achieve.

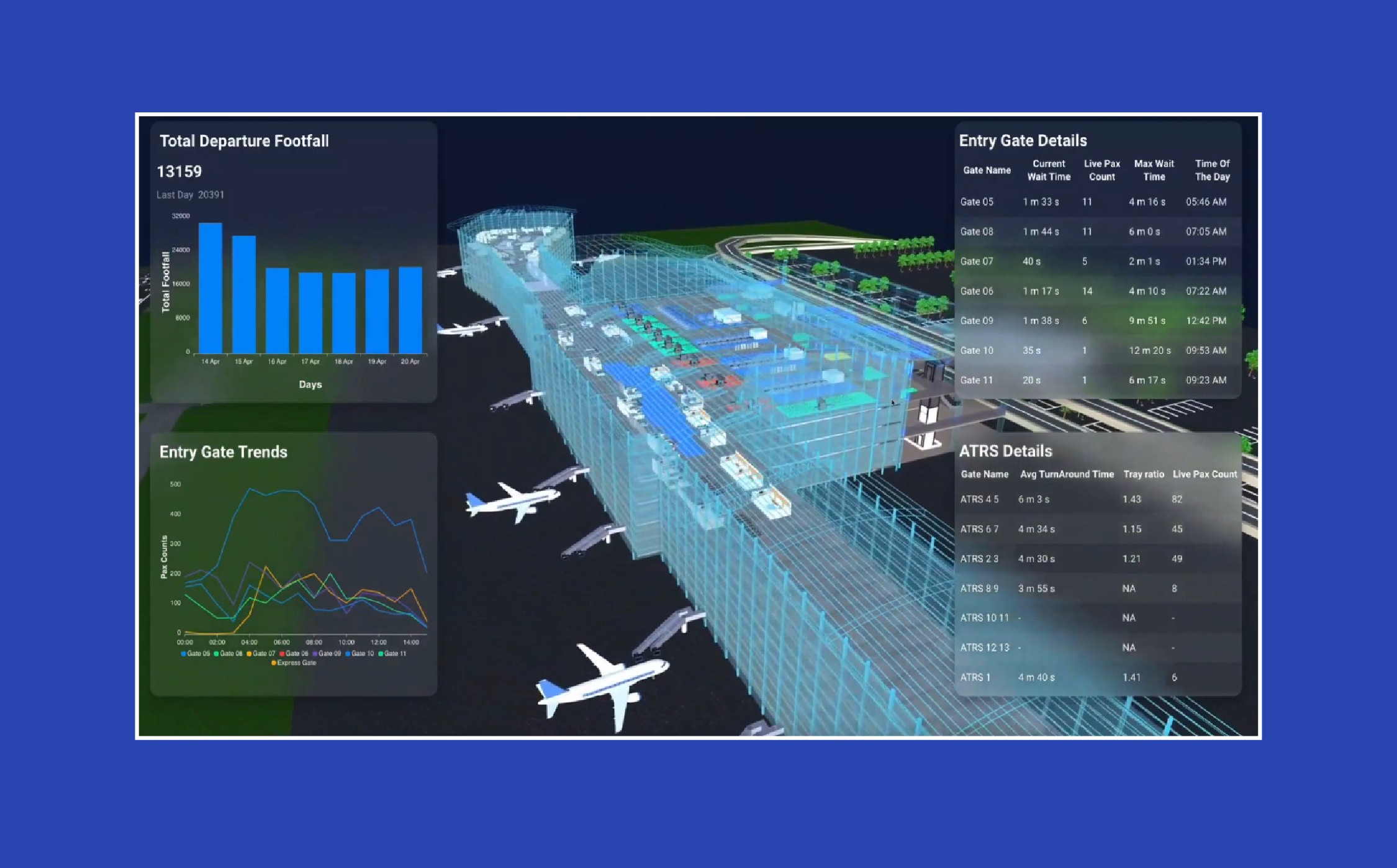

A digital twin for APOC in airports is a virtual representation of the entire airport ecosystem, encompassing its infrastructure, facilities, systems, and operations. By leveraging digital twin technology, airports can gain a holistic view of their entire operational landscape, facilitating data-driven decision-making, improving efficiency, and enhancing overall safety and improving passenger satisfaction.

For quite some time now, our innovative IT solutions, including APOC are reshaping the future of airport operations. #TeamWAISL has been deeply immersed in researching digital twin technologies, aiming to revolutionize airport ecosystems and position them as intelligent contributors in the aviation sector.

Our dedicated exploration into digital twin technology and other cutting-edge advancements has culminated in our latest offering – the Airport Digital Solution (ADS), powered by a locational intelligence and situational awareness platform.

In essence, WAISL’s ADS empowers airport operators with data-driven insights, ushering in the era of ‘Total Airport Management.’ This solution integrates critical airport operations into a unified control center, driven by a digital twin-powered Command and Control Centre. It seamlessly incorporates new technologies like AI, IoT, video cloud, big data, and an integrated Communication Platform (ICP) to elevate passenger satisfaction and optimize APOC airport operational efficiencies.

The ADS integrates essential edge information from diverse sources such as IP Cameras, wired and wireless systems, Bluetooth sensors, and operational systems, consolidating them into a cohesive framework. Airport operators and managers can proactively anticipate changes, minimize operational disruptions, and maximize overall performance. Featuring predictive analytics, faster response times, operational efficiencies, and the capability to unlock new revenue streams, any airport implementing this solution stands to evolve into a key player rather than a mere stakeholder in the aviation sector.

=====

Are you in search of cutting-edge airport technology solutions that use digital twin technology? Great! Let WAISL show you how it can do wonders for your airport ecosystem. Drop us a message at [email protected], and one of our representatives will get in touch with you.

Citations: